mello dude

Half genius, half dumazz whackjob foole

Awesome stuff...

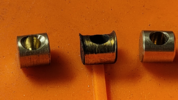

Thanks for the information- Good to have an alternate if needed.Clutch lever bushing

The Honda part Number 2285-MBO-006 is $10

The Suzuki part number 59892-08A00 is $3 and exactly the same part.

WHAT?? What if that brass isn't MilSpec in accordance with the OEM part. It could seize imparting clutch functionality and send you careening into traffic where you might be mowed down by a Farms in Berkley truck and die a fiery death!However, one I'm not terribly concerned over it given this part's application.

Indeed. As I rethink my analysis a fiery death doesn't seem particularly likely. Much ado I say. However as I don't possess any High School Metal Shop kit I'd be tempted to investigate the Suzuki Alternative. But even if I had a little Unimat I'd be tempted to roll my own. Just because that looks so damn cool. Good on ya STR!Its failure mode will be slow, and easily monitored. I'm not worried, frankly. Will report back after a few thousand miles of service.

Nice one. Motorcycles are an amalgam of all sorts of parts from many manufacturers, so (one assumes) the OEM parts price includes a significant mark-up to cover the repackaging and warehousing costs. Suzuki must be more efficient at this part....Clutch lever bushing

The Honda part Number 2285-MBO-006 is $10

The Suzuki part number 59892-08A00 is $3 and exactly the same part.

Thanks for the information- Good to have an alternate if needed.

Curious to know how you found this out.

Correction in case anyone is searching online by part number- P/N is 22885-MB0-006. (Zero instead of O, as in oh)

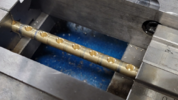

It sounds like a lot of effort for a tiny piece, but I've often gone down that rabbit hole myself.

And knowing Honda, they probably put as much or more into the original design. If anything, the cost of the original is somewhat justified by all of your own machinations to reproduce it.

My guess for material is a good corrosion resistance and easy turning/machining despite having been cold worked for strength. Annealed rod would not be wise. My stab would be a 623 aluminum bronze.

Unfortunately the bore in the clutch lever is often worn as well necessitating replacing the lever. I wish that they had made the clutch lever using the same materials as the brake lever. In that case only the sacrificial bushing would need to be replaced most often.You replace this instead of wallowing out the aluminum of the lever or wearing down the rod extending from the master cylinder piston.

Outstanding cross reference!Awesome skills and a cool project, HOWEVER this exact part is available as a Suzuki piece for $3.

IIRC, calipers were not the measuring instrument of choice. My high school shop had micrometers - beat up but still working.

Nice one. Motorcycles are an amalgam of all sorts of parts from many manufacturers, so (one assumes) the OEM parts price includes a significant mark-up to cover the repackaging and warehousing costs. Suzuki must be more efficient at this part....