Services the rear wheelYou'll know you're good when you can turn a figure eight inside the H-shaped space of four parking spaces.

Tell us about your HUD.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do with your ST1100/ST1300 today?

- Thread starter Mellow

- Start date

I got new tires for my Red & Black 1300. Bridgestone Battleax T32. This was the first time taking the rear wheel off. It wasn't as bad as I feared and went pretty smoothly (except I let some gear oil leak out). Clean and coated all the splines. I noticed the small end of the drive shaft was completely clean and dry (no paste). I put a smidge of moly paste on there just to be safe. Everything checked out good, except I'll probably need brakes in another 500-1,000 miles. One to-do deleted and one added...

woodybelle

Site Supporter

When taking the rear wheel off there should be zero chance of gear oil leaking out of anywhere. Also the drive shaft is not exposed when taking the rear wheel off but the driven wheel splines are and should be well lubricated but I am not sure we are talking apples to apples here. Can you elaborate ?

Well, I'm new to this - so who knows. When I removed the rear wheel, the gearbox rotated (heaviest part pointing at ground) a slow drip of gear oil came out around the splined stub. I examined the area for any type of oil seal and didn't see one clearly. Next I discovered an oil seal on the drive shaft (laying in the housing on the bike. Once I popped the gearbox off the wheel and set it on cardboard (wheel side down) the dripping stopped.When taking the rear wheel off there should be zero chance of gear oil leaking out of anywhere. Also the drive shaft is not exposed when taking the rear wheel off but the driven wheel splines are and should be well lubricated but I am not sure we are talking apples to apples here. Can you elaborate ?

Now, I studied the oil seal on the shaft and it looked in good condition. The shaft slid out of the enclosure with no resistance whatsoever, so everything got a good clean and examination. The tiny splines on the forward end of the shaft were clean and dry. The rear splines that go into the gearbox were clearly lubed several times. It looked more like grease than paste - so I cleaned it and reapplied moly paste to ALL splines accessible to me. I also replaced the o-ring that was on the wheel (male splines). There was some very minor grease leakage here, probably from sloppy application/assembly; but I replaced the o-ring anyway. I also cleaned up all the grease between the o-ring and plastic shroud (not really visible once reassembled) because I could and thought it was sensible.

The shop manual shows an oil seal buried inside the ring gear - which in retrospect may be what allowed the gear oil to leak if it was worn. I guess maybe I can investigate replacing this, however - I suspect It requires removing the ring gear? I can't really tell from the pictures. One more item on my to-do list

Pictures would help a lot if you canWell, I'm new to this - so who knows. When I removed the rear wheel, the gearbox rotated (heaviest part pointing at ground) a slow drip of gear oil came out around the splined stub. I examined the area for any type of oil seal and didn't see one clearly. Next I discovered an oil seal on the drive shaft (laying in the housing on the bike. Once I popped the gearbox off the wheel and set it on cardboard (wheel side down) the dripping stopped.

Now, I studied the oil seal on the shaft and it looked in good condition. The shaft slid out of the enclosure with no resistance whatsoever, so everything got a good clean and examination. The tiny splines on the forward end of the shaft were clean and dry. The rear splines that go into the gearbox were clearly lubed several times. It looked more like grease than paste - so I cleaned it and reapplied moly paste to ALL splines accessible to me. I also replaced the o-ring that was on the wheel (male splines). There was some very minor grease leakage here, probably from sloppy application/assembly; but I replaced the o-ring anyway. I also cleaned up all the grease between the o-ring and plastic shroud (not really visible once reassembled) because I could and thought it was sensible.

The shop manual shows an oil seal buried inside the ring gear - which in retrospect may be what allowed the gear oil to leak if it was worn. I guess maybe I can investigate replacing this, however - I suspect It requires removing the ring gear? I can't really tell from the pictures. One more item on my to-do list

My wife and two of the kids headed out to eastern Washington to go camping with the cousins yesterday. I received a phone call around 5pm from the wife informing me that they were stranded because the car overheated and roadside wouldn’t bring coolant. I grabbed two gallons of coolant and a quart of oil and headed out. Unfortunately, WADOT was blasting in the mountains along I90 and stopped traffic for an hour  But I did meet three guyswho were headed out for 18 days of epic motorcycle destinations including the Tail of the Dragon. They even extended an invitation to me to go

But I did meet three guyswho were headed out for 18 days of epic motorcycle destinations including the Tail of the Dragon. They even extended an invitation to me to go Arrived at the stranded wife after dark and didn’t see the coolant streaming out of a hose bib missing its hose

Arrived at the stranded wife after dark and didn’t see the coolant streaming out of a hose bib missing its hose

Our other family members coming down blew two tires and the radiator in their truck. They ended up at a KOA in Leavenworth so we limped our car to them.

There’s a NAPA half mile away so I was able to get a bib nipple and worm clamp. We then dropped the brother in law’s truck at a local shop.

I get a day off work!!!

Blewett pass is under construction for several miles so if you need curves look elsewhere.

Our other family members coming down blew two tires and the radiator in their truck. They ended up at a KOA in Leavenworth so we limped our car to them.

There’s a NAPA half mile away so I was able to get a bib nipple and worm clamp. We then dropped the brother in law’s truck at a local shop.

I get a day off work!!!

Blewett pass is under construction for several miles so if you need curves look elsewhere.

Last edited:

Okay, I studied the manual a bit more. When you guys pull the rear wheel, does the driveshaft come with it? Mine separated from the pinion and stayed in the housing. Oil came out of the pinion without the shaft installed. The manual appears to show the two parts coming off the bike together, and then manually separated. I suspect my oil seals are okay, but my stopper ring is weak (it says replace each service?). Very interesting and complicated. The other oil seal on the ring gear is fine (I got confused looking at the diagrams in the manual) - no oil leakage from this area at all.

Hope the picture helps. It shows the oil seal that I mentioned that is on the driveshaft. This seal goes into the pinion when assembled. I think I should have coupled the two together then inserted the driveshaft into the housing but I did not. I guess I'll see what happens over the next few weeks. Worst case is I go back in and replace that oil seal on the driveshaft and the "stopper ring."

Hope the picture helps. It shows the oil seal that I mentioned that is on the driveshaft. This seal goes into the pinion when assembled. I think I should have coupled the two together then inserted the driveshaft into the housing but I did not. I guess I'll see what happens over the next few weeks. Worst case is I go back in and replace that oil seal on the driveshaft and the "stopper ring."

Attachments

- Joined

- Oct 26, 2020

- Messages

- 2,059

- Location

- Makefield Highlands PA

- Bike

- 2016 ST1300P

- 2025 Miles

- 001084

I went back and read your previous posts also, are you trying to do something with the drive shaft? I thought I read you were changing tires, only the rim comes off for that. Do you have any current pictures of the open space where the rim and tire go? Curious about how much disassembly you have embarked on.Okay, I studied the manual a bit more. When you guys pull the rear wheel, does the driveshaft come with it? Mine separated from the pinion and stayed in the housing. Oil came out of the pinion without the shaft installed. The manual appears to show the two parts coming off the bike together, and then manually separated. I suspect my oil seals are okay, but my stopper ring is weak (it says replace each service?). Very interesting and complicated. The other oil seal on the ring gear is fine (I got confused looking at the diagrams in the manual) - no oil leakage from this area at all.

Hope the picture helps. It shows the oil seal that I mentioned that is on the driveshaft. This seal goes into the pinion when assembled. I think I should have coupled the two together then inserted the driveshaft into the housing but I did not. I guess I'll see what happens over the next few weeks. Worst case is I go back in and replace that oil seal on the driveshaft and the "stopper ring."

Went 120km to try my new plug/patch

It's all put back together now. I didn't see any way to remove the rear wheel without disconnecting the final drive assembly. Then remove the assembly from the wheel prior to taking the wheel to shop for new tire. Everything went back together smoothly. Drives fine... as best I can tell.I went back and read your previous posts also, are you trying to do something with the drive shaft? I thought I read you were changing tires, only the rim comes off for that. Do you have any current pictures of the open space where the rim and tire go? Curious about how much disassembly you have embarked on.

ST1100Y

Site Supporter

oh dear...It's all put back together now. I didn't see any way to remove the rear wheel without disconnecting the final drive assembly. Then remove the assembly from the wheel prior to taking the wheel to shop for new tire. Everything went back together smoothly.

A brief glimpse into the owner's manual would have avoided a lot...

Now you need to realign the final drive on the swing-arm again...

- Joined

- Oct 26, 2020

- Messages

- 2,059

- Location

- Makefield Highlands PA

- Bike

- 2016 ST1300P

- 2025 Miles

- 001084

For future reference maybe;It's all put back together now. I didn't see any way to remove the rear wheel without disconnecting the final drive assembly. Then remove the assembly from the wheel prior to taking the wheel to shop for new tire. Everything went back together smoothly. Drives fine... as best I can tell.

Remove axle nut, remove caliper bracket bolt, remove axle bolt (may need to loosen right muffler to roll down), lift up caliper, pull rim to left side of bike, pull out from under bike. It's easy to read, slightly harder to do. I put two boards under the wheel for a lever, some take off rear mud guard.

JohnK

Site Supporter

Took a short run 80 miles round trip to Lacey to visit a fellow member selling ST stuff. It’s warm today in WA. But get out in the morning makes a diff. Just like garage sale run - got a clear view with a vent - going to try that out for a while. See if that center vent helps with a nice breeze on the jacket

I'll second the 'oh dear..."It's all put back together now. I didn't see any way to remove the rear wheel without disconnecting the final drive assembly. Then remove the assembly from the wheel prior to taking the wheel to shop for new tire. Everything went back together smoothly. Drives fine... as best I can tell.

Once the Brake Stopper Bolt, rear axle and spacers (caliper bracket along with lifting the caliper off the rear disk) are removed, the wheel slides on the spines to the left and wheel can now be extracted from the swingarm.

Edit: Oh yeah, as @Willsmotorcycle said, gotta rotate those mufflers out of the way too

Sadlsor

Site Supporter

I'm one that removes the rear fender, too. I'm doing it on the centerstand, no table or lift available.

But I do lash the centerstand to the front wheel, to avoid pushing it or pushing it off the stand.

But I do lash the centerstand to the front wheel, to avoid pushing it or pushing it off the stand.

Well I’m a dumbass I guess. oh dear...

A brief glimpse into the owner's manual would have avoided a lot...

Now you need to realign the final drive on the swing-arm again...

How does one realign the final drive? I don’t see it in the shop manual, but obviously I’m not always in the proper section.

ST1100Y

Site Supporter

didn't say so... you just didn't know...Well I’m a dumbass I guess.

Sequence is to be found in an article here...How does one realign the final drive? I don’t see it in the shop manual, but obviously I’m not always in the proper section.

Basically you install the rear wheel completely before tighten the nuts holding the f/drive on the swing-arm...

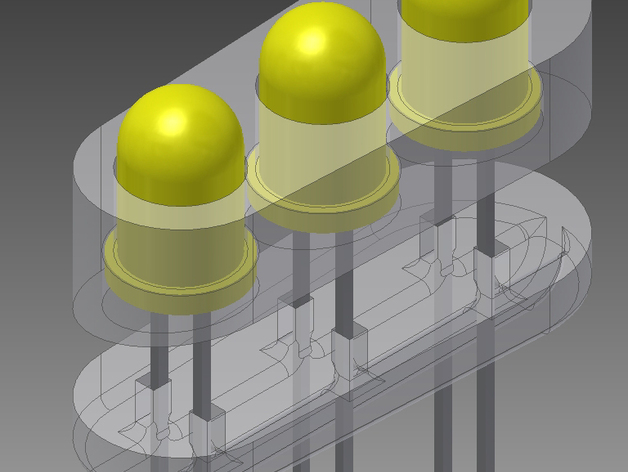

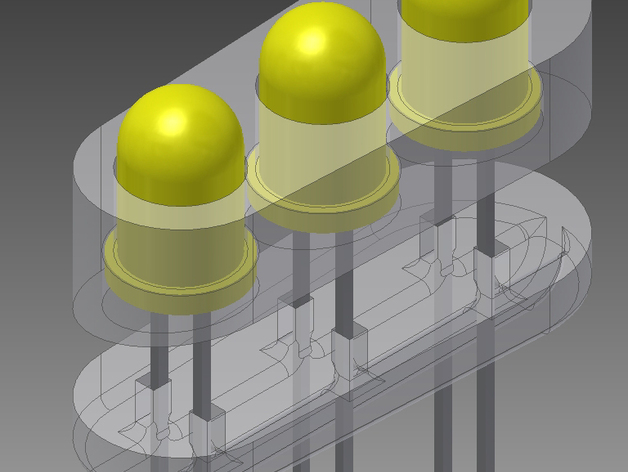

Impatiently awaiting the arrival of my replacement mirror cover, so I rewired both sides with OEM style connectors. I also 3D printed the turn signal reminder pieces so I can install them once the LEDs I ordered arrive.

www.thingiverse.com

www.thingiverse.com

LED Indicator for Honda ST1300 PAN European by Special_Works

This four parts you need for the additional turn indicator in the mirror of a Honda ST1300 PAN European:1x LED-Halter links (STL)1x LED-Halter rechts (STL)2x LED-Halter (STL)6x LED yellow 12V, Ø5mmPrint the 4 parts and assembly together:Insert the LED in the right position into LED-Halter (left...

Oh, and I'm installing my Uni-go style trailer hitch! I'm not sure if it's the real hitch or a reproduction, as the PO told me a local welder built the trailer. I have tip over bars, so I have to replace the lower M10-1.25x50mm bolts with 60mm so they are long enough to then put nuts on the ends. You want to talk about difficult to locate in Stainless Steel! You can find them in black oxide easily, but not SS. The "fine" pitch is what makes it so hard. I ended up compromising and getting some button head SS ones from EBay for $10 for 4. The allen head style that are on there were $5-10 EACH!?

Last edited:

- Joined

- Oct 26, 2020

- Messages

- 2,059

- Location

- Makefield Highlands PA

- Bike

- 2016 ST1300P

- 2025 Miles

- 001084

I think don't on the Ebay ones, I bought them and the heads were going to strip out, I replaced them with the $10.00 each ones.Oh, and I'm installing my Uni-go style trailer hitch! I'm not sure if it's the real hitch or a reproduction, as the PO told me a local welder built the trailer. I have tip over bars, so I have to replace the lower M10-1.25x50mm bolts with 60mm so they are long enough to then put nuts on the ends. You want to talk about difficult to locate in Stainless Steel! You can find them in black oxide easily, but not SS. The "fine" pitch is what makes it so hard. I ended up compromising and getting some button head SS ones from EBay for $10 for 4. The allen head style that are on there were $5-10 EACH!?

Share:

![IMG_2251[1].JPG](/forums/data/attachments/185/185067-50272b7c8d8904dbcb2858ae4fee5654.jpg)